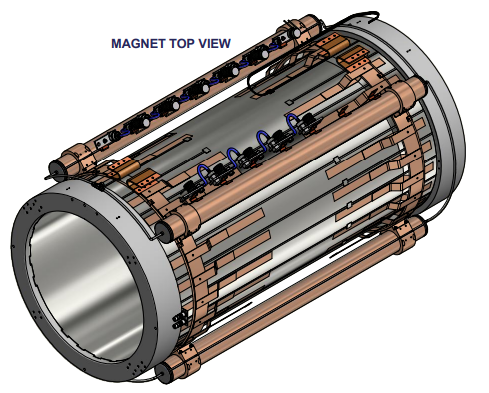

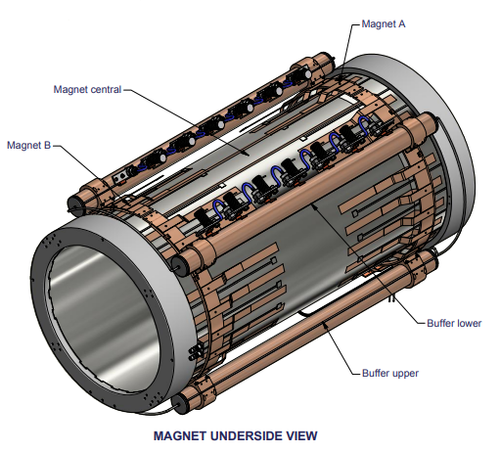

Superconducting Magnets - HGMS cryo magnets

Home of the CRYO - HGMS 5T

PhySep’s superconducting high gradient magnetic separator the - CRYO HGMS 5T - is built with the capacity of producing a 5 Tesla magnetic field, and a throughput of up to 40 tph/unit.

Fine particle separation technology - With almost twice the magnetic force of magnetic separators available, while operating on less than 12kW power consumption.

Available in lab size, pilot size, and several commercial sizes.

Our updated and advanced superconducting separator is even more efficient. With a ‘NextGen’ re-condensing system, which nearly eliminates cooling gas boil off and reducing the need or re-supply of Helium or cryogenic gases. Also, integrated with an in-depth and easy-to-control SCADA and PLC control system. Easy to follow operating controls - for efficient and custom operating controls to suit a custom duty-factor. Allowing easy control of all: valves, flow, processing cycles, washing cycles, magnetic field strength, complete with reports, updates, alerts, and alarms.

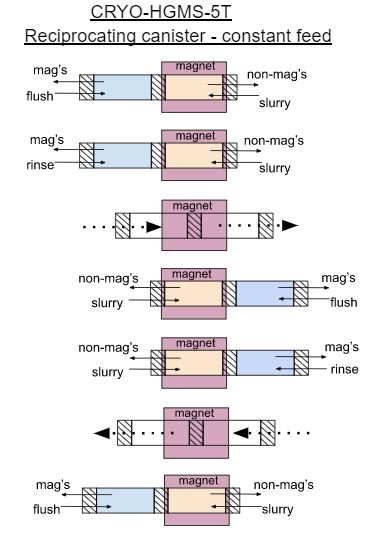

CRYO-HGMS-5T, reciprocating dual canisters allows for:

Continuous feed.

Flush (backwash) and rinse cycles for gangue removal and matrix cleaning in one canister while processing in the second canister and visa versa.

Programmable processing cycle times to suit an optimal duty factor.

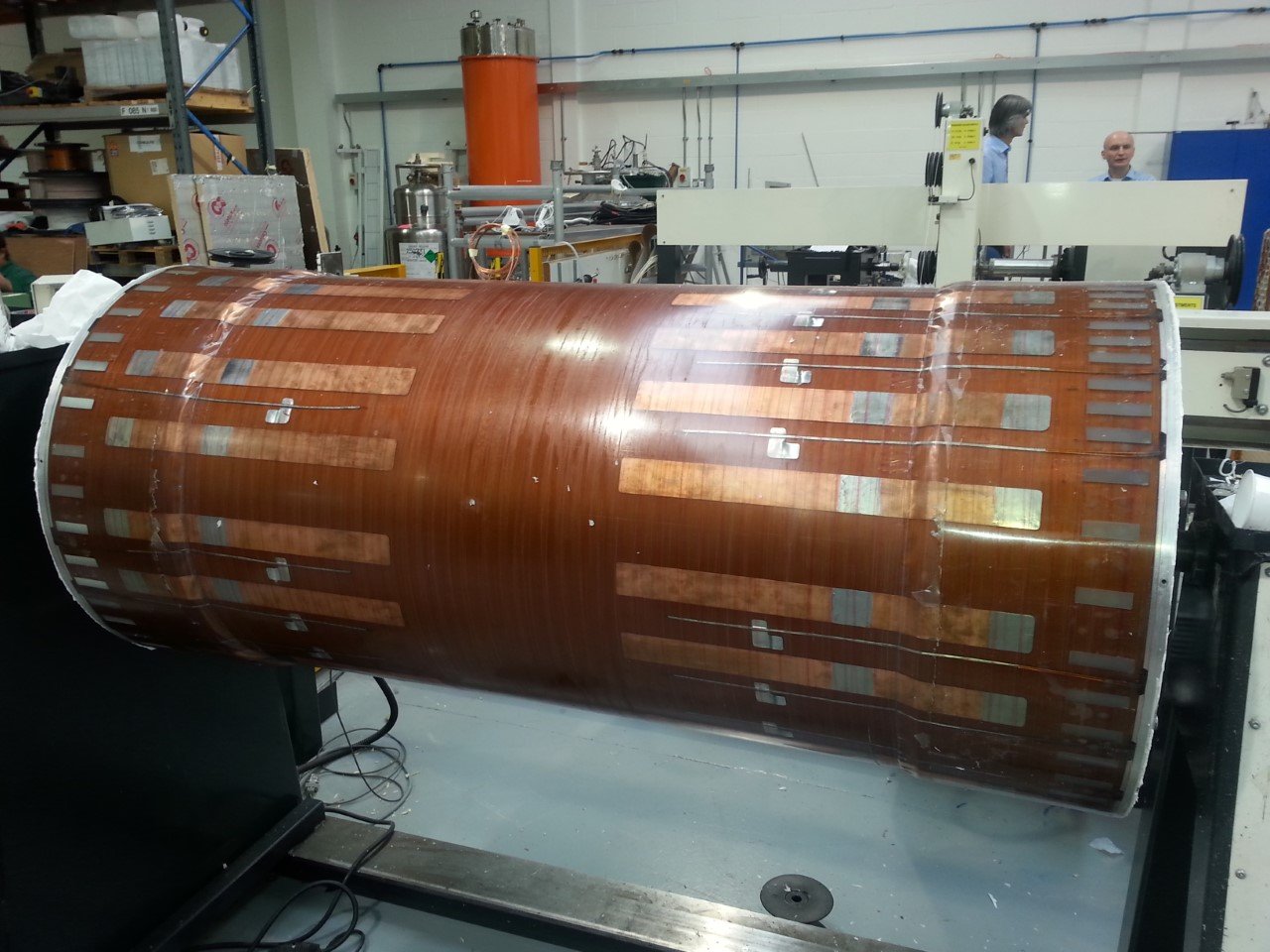

Fine mineral separation: filter canisters can either use either - compressed matrix or stacked wire mesh.

Matrix (Filtration Media) size chart (mesh sizes also available):

Benefits of Superconducting High Gradient Magnetic Separation (HGMS)

When comparing magnetic fields a key parameter:

for paramagnetic materials c and v will be the same for all systems

hence F = X v B . V B,

indicating that an increase in B or V B, will increase the capture force.

Using a 5 Tesla field gives a 2.5 increase in the capture force over that provided by a 2 Tesla field.

High purity concentrate

Product brightening

Operating on less than 12kW power consumption

Continuous high gradient magnetic separation for fine particles at nearly twice the strength of conventional/industrial electromagnets.

Adjustable magnetic field from 0.5T - 5.0T

SCADA & PLC control system monitors all: valves, actuators, processing cycles, flush and rinse cycles, feed rates, canister reciprocation, magnetic field, and more…

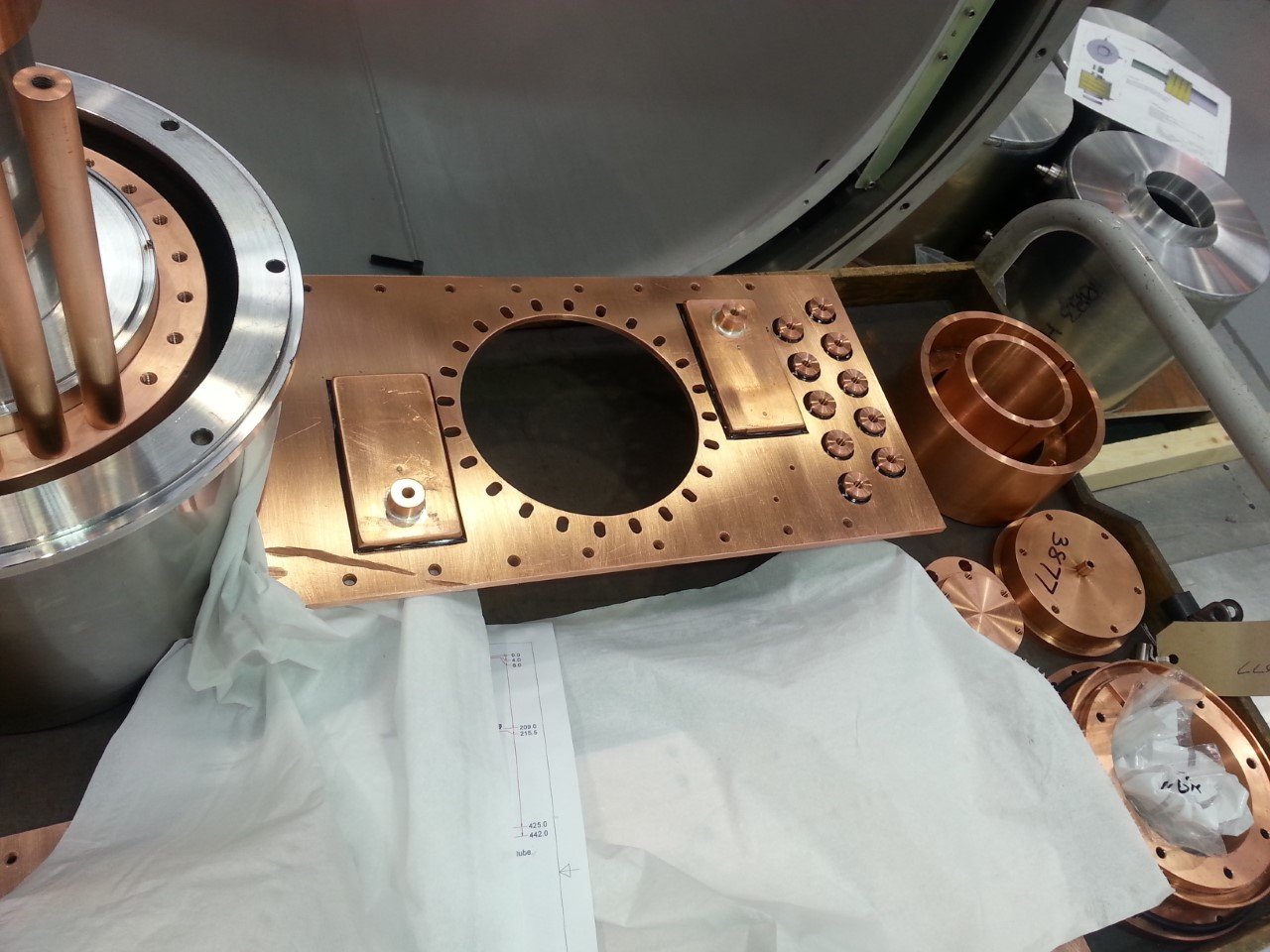

CRYO-HGMS-5T advanced re-condensing system:

Self-contained perpetual cooling gas buffer volume.

Reducing cryogenic gas boil off

Eliminating the constant demand for gas re-supply, making operating costs even lower.

Electromagnets

The HGMS process of separating or filtering is created by magnetizing a matrix or filter media between magnetic poles. Filtering fine and weakly magnetic particles from fluid suspension. It is widely used in the mineral processing industry for concentration of magnetic ores and purification of clay, coal and quartz, water purification and biotechnological field for purification of cell, even protein and DNA.

Electromagnetic separators can produce a higher magnetic field than permanent magnetic rolls. Special magnet configurations may be used to produce high-intensity magnetic fields, while ‘superconducting’ technology enables even stronger electrically charged magnetic fields. These high-intensity fields permit the removal of feebly magnetic contaminating minerals from concentrates of non-magnetic minerals such as glass sands, talc, kaolin, diatomaceous earth and bauxite. This also means that the power requirements of superconducting system are greatly reduced when compared to conventional wet high intensity magnetic separators (WHIMS).

Lab sized electromagnets both wet (WHIMS) and dry (HGMS) available.

Industrial scale electromagnets and spare parts available.

Contact us about electromagnets - HGMS magnets - or superconducting HGMS magnets, spare parts, or service.